Hitech Enviro Solutions is engineered for high flow rate sedimentation and settling of flocculated wastewater streams. These units are pre-engineered, pre-assembled and factory tested ensuring reliable operation and minimising site installation and start-up time.

High flow rate sedimentation and settling in a Lamella Clarifier works by having a flocculated liquid/solid stream (e.g. raw wastewater, activated sludge mixed) flow upwards between inclined Lamella Plates. The flocculated solids tumble down to the plate surface by gravity and to a sludge collection hopper. The clarified water overflows through a weir that exits the top of the Lamella Clarifier.

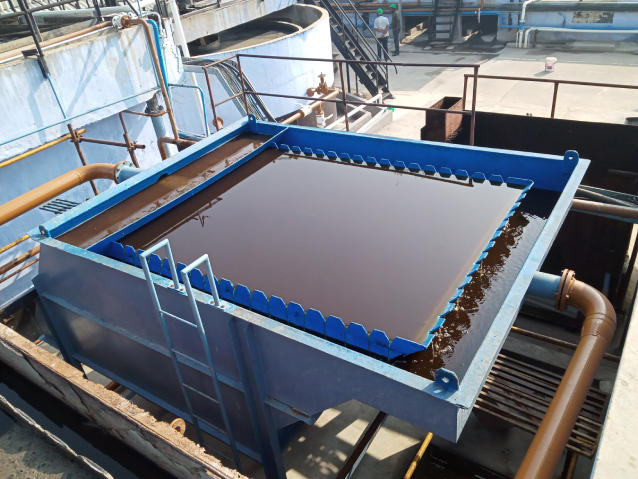

Lamella Clarifier is a compact, inclined plate type of clarifier. It is used for clarification of water, waste water and liquid having suspended and colloidal particles. Principle of Lamella Clarifier is based on settling under gravity, providing number of inclined plates to give large projected surface area.

The Lamella Clarifier provides a means of water clarification at a large saving of plant surface area. The clarifier consists of a series of inclined overlapping plates, which are arranged to form a separate sedimentation chamber or the cells between each pair of adjacent plates. The overlapping additive projected area of several plates is a factor of increased surface settling area proportioned to the number of plates used.

Before entering to Lamella Clarifier, water is first fed to Flash Mixer and Flocculation Tank (FMFT). Chemicals like alum, ferric chloride, lime are added in flash mixer in which high-speed agitator is provided for proper mixing of chemicals in water. Water from flash mixer enters in flocculation chamber in which paddle type agitator is provided for gentle mixing. Polymer is added for flocculation of coagulated particles. Sufficient residence time is provided in this chamber for particles to become heavy before entering into Lamella Clarifier.

Static mixer can replace the flash mixer. In such case, chemicals were added prior to static mixer. The zigzag vanes are provided in static mixer to do proper mixing of chemicals.

The pre-treated feed stream enters the Lamella and transverses through feed ducts longitudinally, along each side of the Lamella plates, through a bottomless distribution duct. The liquid/solid feed stream then enters each plate chamber near the bottom section of the plates and flows upward between them. As the feed stream moves upwards, solids settle downward by the plates descending a short distance onto the surface area provided by the plates. Solids continue to slide down the plate surfaces to a collection hopper.

Near the top of each plate, water leaves each cell through a pair of circular openings in the adjustable weir plate located along each side of the clarifier. The weir plate should be set horizontally and in level so as to provide proper distribution of liquid through each circular opening. It should also be set at a height to provide a design water level below top of the tank.

Sludge is periodically removed by opening the drain valve provided in the hopper bottom of the Lamella clarifier.

| • Flow entry | The flow enters from both sides of the plate. Distribution and entry velocities are minimum to optimise the hydraulic flow regime, resulting in full plate utilisation, maximum efficiency and better effluent quality. |

|---|---|

| • Weir take-off | A weir launder provides an effective weir length. The weir has orifices on either side of each plate. |

| • Removable plates | Individual plates are easily removable even during operation, making the unit very simple to maintain. The design offers flexibility to handle changes in influent characteristics. |

| • Hopper Arrangement | Several options are available for sludge storage. The standard arrangement is a hopper bottom with a structural support frame. A second option is to mount the lamella clarifier on top of a thickener in order to achieve a higher solids concentration, while providing a large sludge volume. |